Durable Polycarbonate Polyurethane

MPC’s Durethane® XL is a high-performance polyurethane engineered for extreme durability in the harshest operating environments. Developed using proprietary polycarbonate-based chemistry, Durethane® XL offers superior resistance to heat, aging, hydrolysis, and chemical exposure, making it the most rugged formulation in the Durethane® family. Whether molded or foamed, this material excels in mission-critical applications across defense, marine, oil & gas, and heavy machinery, where long-term reliability and minimal maintenance are essential. Its ability to maintain physical integrity under pressure, temperature swings, and corrosive conditions makes it a trusted choice for designers building components that simply cannot fail.

Benefits:

- Extends component life and reduces maintenance costs

- Performs reliably in high temperatures without sacrificing performance

- Superior chemical and humidity resistance

- Can be made into solid, foam or conductive materials

Complete this form to access & download our technical documentation.

Product Spotlight – Polyurethane Bumpers for Conveyor Systems

In high-speed, high-impact conveyor environments, MPC’s custom polyurethane bumpers deliver the protection and performance that industrial systems demand. Designed to absorb shock, reduce vibration, and minimize noise, these bumpers safeguard equipment and materials while extending system life. Whether used in automated packaging lines, material handling systems, or cleanroom conveyors, our bumpers are engineered to perform under pressure—resisting abrasion, chemicals, and temperature extremes.

Key Advantages of MPC’s Polyurethane Bumpers for Conveyor Systems:

- Impact Absorption: Cushions collisions and protects sensitive components from damage

- Noise Reduction: Dampens vibration and sound for quieter, more efficient operation

- Chemical & Wear Resistance: Withstands harsh environments and continuous use without degradation

- Custom Fit & Formulation: Tailored hardness, geometry, and construction to match the needs of your conveyor system

Complete this form to access & download our technical documentation.

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

Durethane® XL Durable Polyurethane for Mission Critical Applications

Durethane® XL is built for the toughest environments where conventional materials fall short. Its polycarbonate-based chemistry gives it exceptional resistance to heat, chemicals, and mechanical stress, making it ideal for components that must perform reliably under extreme conditions. Whether molded into solid parts or foamed for cushioning and sealing, Durethane® XL is trusted across industries that demand long-term durability and minimal maintenance, even in corrosive, high-pressure, or high-humidity settings.

Common Applications for Durethane® XL:

- Military & Defense Equipment: Rugged components that withstand field deployment and harsh operating conditions

- Energy Production: High strength seals, rollers and pads for corrosive and high-temperature environments

- Heavy Machinery & Automotive: Durable wear parts that resist abrasion, impact, and chemical exposure

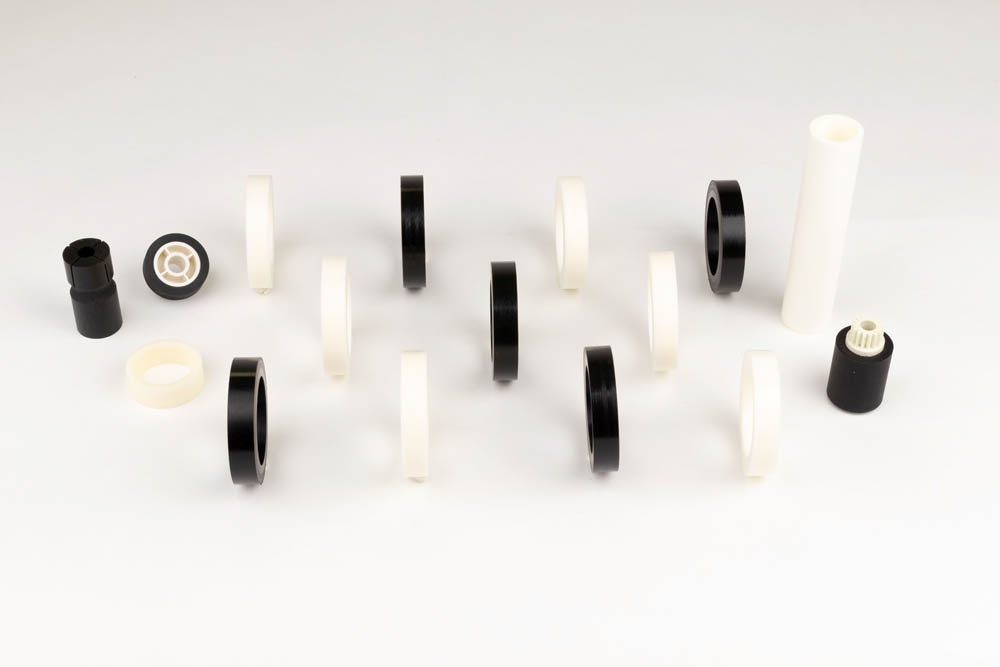

- Media Handling: Long-lasting rollers, bumpers, and gears that perform reliably in high-speed, high-humidity environments

Case Study

A global OEM in the printing industry partnered with MPC to solve a complex challenge: designing components that could reliably move paper through high-speed printing machines while enduring extreme temperatures and humidity. Our team developed a custom Durethane® XL formulation with a precise coefficient of friction, engineered electrical conductivity, and enhanced durability to meet the application’s unique demands. Through close collaboration and iterative testing, we delivered a solution that improved paper handling performance, reduced wear, and significantly lowered maintenance costs—resulting in greater uptime and long-term reliability across the customer’s global installed base.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.