Polyurethane Belts

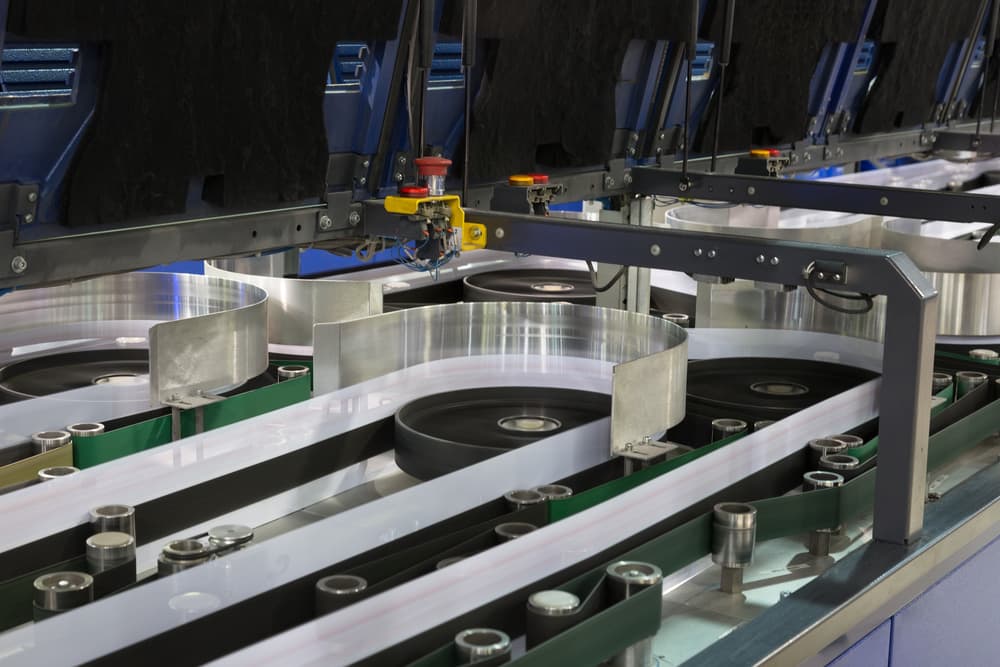

MPC’s custom polyurethane belts are engineered for high-performance applications where durability, precision, and reliability are non-negotiable. Unlike traditional rubber belts, our thermoset polyurethane formulations resist wear, stretching, chemicals, and temperature extremes, making them ideal for industries like packaging, robotics, and food processing. Each belt is tailored to your exact specifications, ensuring optimal grip, flexibility, and longevity in even the most demanding environments. Whether you’re upgrading legacy systems or designing new equipment, MPC delivers belt solutions that keep your operations running smoothly and efficiently.

Solutions:

- Timing Belts

- Flat Belts

- Foam Belts

- Multi-layer Belts

Complete this form to access & download our technical documentation.

Product Spotlight – Closed-Cell Foam Belts

MPC’s closed-cell foam belts are designed for precision handling in high-speed, demanding applications like packaging, paper converting, and food processing. Made from proprietary thermoset polyurethane, these belts feature a non-porous, resilient structure that resists environmental conditions, deformation, and wear, delivering consistent performance and extending machine uptime.

Key Advantages of MPC’s Closed-Cell Belts:

- Self-Cleaning Material: Closed-cell structure allows dirt and debris to be shed as the belt moves in operation for extended component life

- Precision Grip: Maintains consistent coefficient of friction as material wears to ensure predictable motion through lifecycle

- Shape Retention: Prevent stretch and deformation for longer belt life and reduced downtime

- Customizable Materials: Tailored to the specific needs of your belt application including hardness, surface finish and electrical conductivity

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs.

High-Performance Belts for Complex Applications

MPC’s custom polyurethane belts are built for precision, durability, and performance in demanding industrial environments. Leveraging our proprietary material formulations, these belts outperform traditional rubber and plastic alternatives by resisting wear, stretching, chemicals, and temperature extremes. Polyurethanes offer exceptional flexibility under load, maintain their shape over time, and can be tailored to your exact specifications, making them ideal for packaging, robotics, and cleanroom applications.

Advantages of MPC’s Custom Polyurethane Belts:

- Tailored Polyurethane Formulations: Engineered to meet the exact performance demands of your application

- Precision Manufacturing: In-house molding and machining capabilities ensure tight tolerances, consistent quality, and reliable performance

- Customizable Geometry: Designed to fit your product’s unique specifications and functional requirements

- Made in the USA: Domestic production enables fast lead times and responsive engineering support

- Trusted by Global OEMs: Proven in mission-critical applications across robotics, food processing, media handling, and semiconductor industries

Case Study

A leading manufacturer in the media handling industry approached MPC with a challenge: reengineering a belt for a high-speed system that transports highly delicate media through over one million cycles per day. The application demanded a precise coefficient of friction to grip without damaging the material, the ability to conform to surface imperfections, and exceptional abrasion resistance to withstand continuous use. MPC’s engineering team partnered closely with the customer to develop a custom three-layer belt solution, featuring a closed-cell foam contact layer for gentle media handling, a soft solid layer for drive engagement, and a reinforced core to prevent stretch. The result was a high-performance belt that improved system reliability, reduced maintenance, and enabled the customer to confidently launch a product optimized for performance and durability.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.