Energy

the Energy Industry

MPC’s engineered materials power performance where it matters most—deep in the heart of the energy sector. From offshore rigs to wind farms, our advanced polyurethane solutions are built to thrive in the toughest environments, delivering unmatched durability in oil, gas, and renewable applications.

SOLUTIONS:

- Vertebrae Bend Restrictors (VBR)

- Sealing Elements

- Mud Pump Valves & Pistons

- Wire Saw Rollers and Pulleys

- Custom Polyurethane Products

Complete this form to access & download our technical documentation.

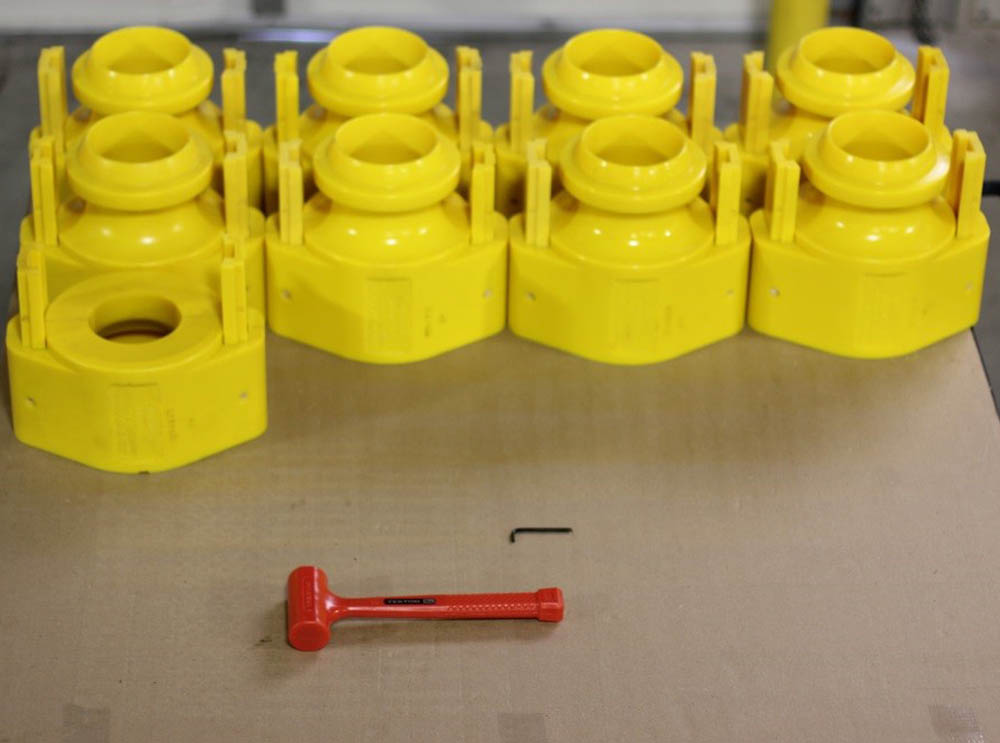

Product Spotlight - Vertebrae Bend Restrictors (VBR)

MPC’s Vertebrae Bend Restrictors (VBRs) are engineered to provide essential, long lasting protection for subsea cables, risers, and umbilicals, ensuring they withstand the harsh environments and high mechanical stresses common to offshore and underwater applications. Whether you require the streamlined, efficient installation of our boltless VBR systems or the traditional bolted VBRs, our advanced polyurethane solutions are built for durability and high performance where it matters most.

Advantages of MPC’s Boltless VBR System:

- No Hardware Hassles: Eliminates bolts and metal components, simplifying installation and reducing the need for sourcing additional hardware

- Corrosion Resistance: Made from MPC’s engineered polyurethanes, these VBRs thrive in harsh marine environments without rust or degradation

- Faster Installation: Fewer parts mean quicker setup, saving valuable time for offshore teams and minimizing downtime

- Lower Project Costs: Reduces expenses tied to hardware, transport, and installation labor, delivering real savings over traditional systems

Complete this form to access & download our technical documentation.

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

Advanced Materials for Demanding Energy Applications

Polyurethane is a powerhouse material for the energy industry, engineered to thrive in extreme environments where rubbers, metals, and plastics often fall short. Whether in oil, gas, or renewable energy applications, MPC’s engineered materials deliver the durability, flexibility, and customization needed to keep systems running reliably and efficiently. From offshore rigs to wind farms, polyurethane components offer a smart alternative that reduces weight, resists corrosion, and adapts to complex design requirements.

Advantages of Polyurethane in Energy Applications:

- Lightweight Strength: Exceptional strength-to-weight ratio enables more efficient designs for components like seals, rollers, and housings

- Corrosion Resistance: Polyurethane thrives in harsh environments, including saltwater, humidity, and chemical exposure

- Long-Term Durability: Polyurethanes maintain performance under repeated stress, vibration, and environmental extremes, reducing maintenance and extending service life

- Design Flexibility: Easily tailored for specific geometries, hardness, and mechanical properties required across energy applications

Case Study

An offshore energy customer approached MPC to replace a machined metal enclosure used in a sensitive electronic assembly exposed to harsh marine conditions. Their existing solution was costly, prone to corrosion, and difficult to scale. Leveraging our cast polyurethane process, we engineered a custom enclosure that met stringent dimensional and performance specifications while offering superior resistance to saltwater, humidity, and temperature extremes. The result was a durable, lightweight alternative that not only outperformed marine-grade metals in corrosive environments but also delivered substantial cost savings and streamlined production, helping the customer scale efficiently without compromising reliability.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.