Quality Assurance

Quality is built into our products, from start to finish. We follow strict process controls, detailed documentation, and ISO 9001:2015-certified processes. In-house testing validates material properties, dimensions, and part performance, giving you confidence your parts will perform as designed.

Capabilities

- ISO 9001:2015 certified

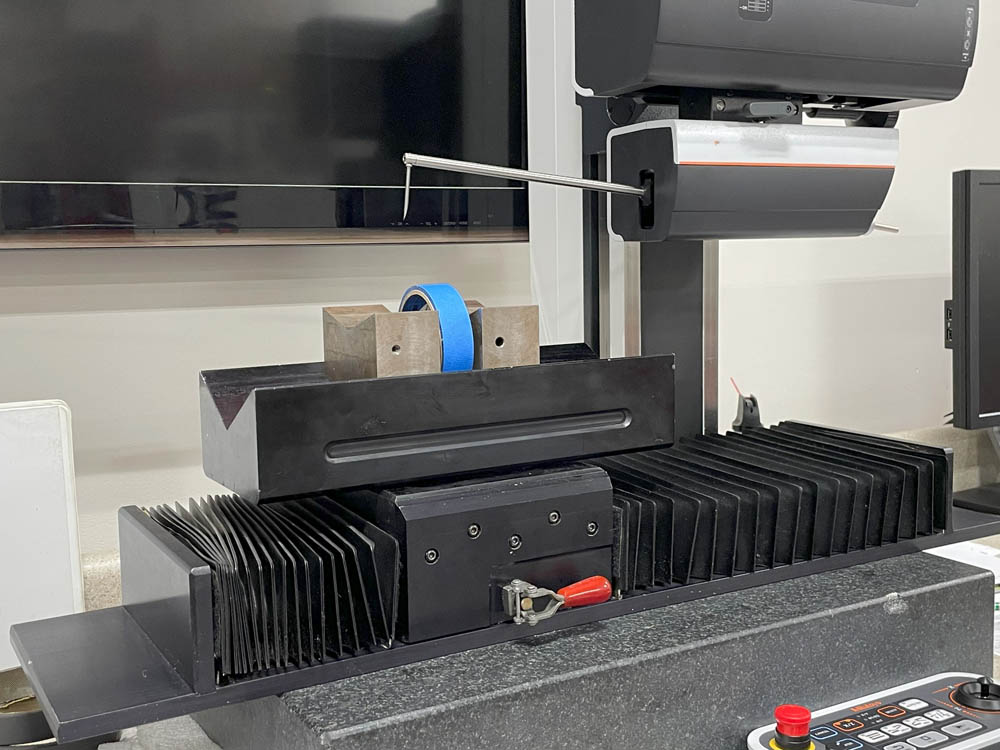

- In-house material and specialty testing

- Dimensional and visual inspection

Complete this form to access & download our technical documentation.

MPC's Commitment to Quality

At MPC, quality isn’t a checkbox, it’s a mindset. To support our customers’ success, we’ve built a system where every step is traceable, repeatable, and engineered for excellence. That means fewer surprises, faster qualification cycles, and total confidence in the performance of your custom polyurethane products.

How we Deliver Precision, Every Time:

- Raw Material Verification: Every batch of raw materials and subcomponents are inspected before production begins-ensuring conformance from the start

- In-Process Inspection: During molding and secondary operations, we use precision fixtures, gauges, and statistical controls to catch issues before they escalate

- Final Dimensional and Visual Inspection: Each part is rigorously checked against customer drawings and specifications to confirm conformance

- Documentation & Traceability: Every part is traceable to its material lot, work order, and inspection record, making audits and qualifications seamless for your team

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

Quality You Can Count On

Quality assurance isn’t just about catching defects, it’s about building trust, protecting performance, and ensuring every part meets its promise. In industries where precision, safety, and reliability are non-negotiable, MPC’s robust QA processes safeguard your reputation and keep operations running smoothly. From first article inspection to final delivery, quality assurance turns good intentions into measurable results.

Why a Reliable Polyurethane Partner Matters:

- Protects System Performance: Prevents failures that can disrupt operations or damage equipment

- Reduces Downtime: Identifies issues early to avoid costly delays and rework

- Supports Compliance: Meets regulatory and customer requirements with traceable documentation

- Builds Customer Confidence: Reinforces reliability and strengthens long-term partnerships

Case Study

A global medical device OEM approached MPC after repeated delays and poor-quality from their previous vendor were jeopardizing a key product launch and customer trust. With critical timelines and performance standards at stake, MPC stepped in to stabilize their supply chain and elevate manufacturing quality. Our team quickly identified root causes of defects, implemented robust process controls, and scaled production to meet rising demand-all while maintaining tight tolerances and regulatory compliance. As a result, the OEM saw a dramatic improvement in delivery reliability, reduced field failures, and regained confidence across their customer base.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.