Polyurethane Foam

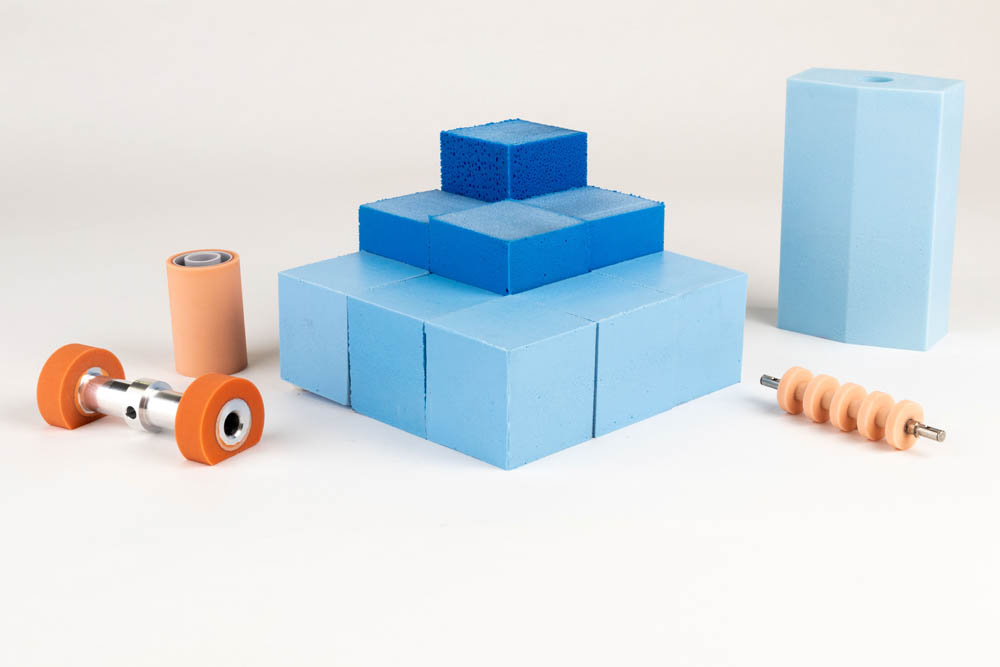

MPC’s Durethane® F polyurethane foam materials are engineered for versatility, durability, and precision across a wide range of demanding applications. Developed using proprietary foaming techniques, Durethane® F features a customizable cellular structure designed to deliver tailored performance in shock absorption, material handling, and more. Whether you’re designing bumpers, rollers, or cushioning components, Durethane® F offers the adaptability and reliability needed to meet your product’s unique requirements.

Benefits:

- Customizable hardness and density

- Tailored open or closed cell structures

- Available with a variety of surface finishes

- FDA-compliant formulations

Complete this form to access & download our technical documentation.

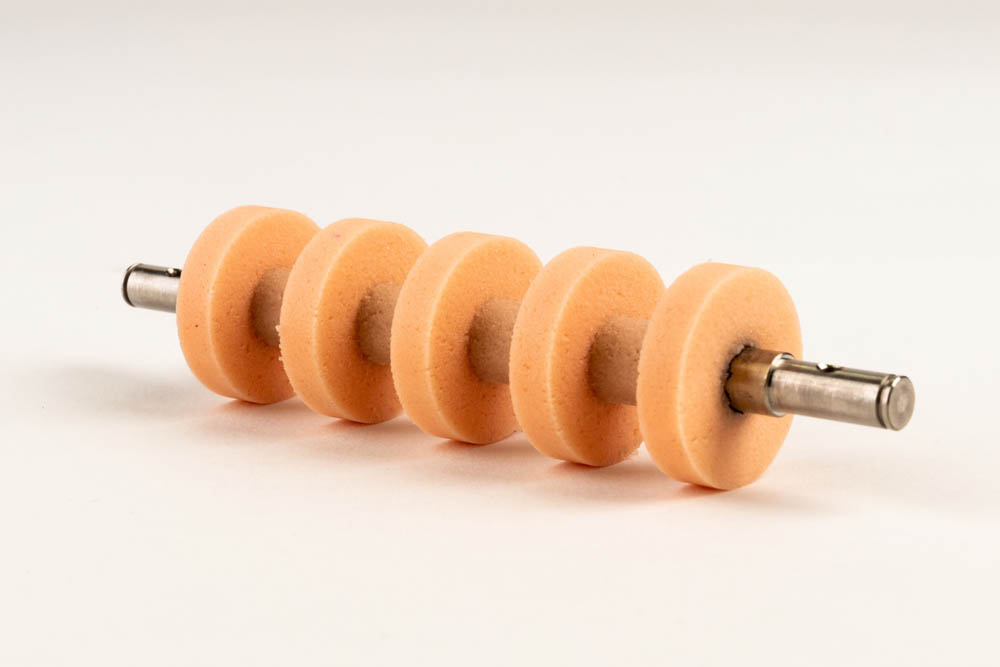

Product Spotlight – Self-Cleaning Foam Rollers

MPC’s self-cleaning foam rollers are engineered to maintain peak performance in mission-critical material handling systems—reducing downtime and extending equipment life. Leveraging Durethane® F formulations, these rollers actively shed dust and debris during operation, helping preserve surface conditions, consistency, and mechanical precision. This is accomplished by the unique cell structure of these engineered foam materials. Available in custom sizes, densities, and finishes, MPC’s self-cleaning rollers are ideal for OEMs seeking low-maintenance solutions that deliver high-impact results.

Key Advantages of MPC’s Custom No-Crush Wheels:

- Active Self-Cleaning: Sheds dust, debris and other contaminants during component operation, reducing buildup and improving system reliability

- Customizable Foam Properties: Available in various densities and hardnesses to match specific product requirements

- Extended Equipment Life: Improved wear resistance improves component life and reduces maintenance costs

- Optimized for Media Handling: Maintains precision in high speed environments like corrugated processing, conveyance, and food processing

Complete this form to access & download our technical documentation.

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

MPC’s Durethane® F Polyurethane Foam

Product designers choose MPC’s Durethane® F polyurethane foam for its unmatched versatility, durability, and precision, especially in applications where durability and long-term performance are critical. Engineered through a proprietary foaming process, Durethane® F offers customizable open- or closed-cell structures and a wide range of physical properties, making it ideal for imaging systems, material handling, bumpers, and more. Whether you’re prototyping or scaling production, MPC’s foam materials deliver consistent quality and design flexibility that help accelerate innovation.

Key Advantages of MPC’s Durethane® F:

- Wide Physical Property Range: Hardness from Shore 10A to 55A, density from 20 to 55 PCF, and tear strength up to 1100

- Lower Tooling Costs: Tooling options reduce upfront investment and accelerate product development

- Rapid Prototyping: Enables quick iteration and testing without long lead times or expensive tooling

- Scalable Production: From prototyping to high-volume manufacturing with robust quality control

Case Study

A global leader in warehouse robotics partnered with MPC to solve a critical challenge: designing a bumper for a robotic conveyor system that could absorb high-impact collisions without compromising the sensitive electronics housed in their autonomous guided vehicles (AGV). The bumper needed to be rugged enough to withstand repeated contact at track corners and intersections, yet resilient enough to prevent damage during high-speed operations. MPC collaborated closely with the customer’s engineering team to develop a custom polyurethane foam formulation optimized for impact absorption and durability. Through rapid prototyping and iterative testing, MPC delivered a solution that enhanced system protection, reduced maintenance costs, and supported the successful launch of the customer’s next-generation robotic conveyance platform.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.