Micro-Molded Products

As industries push the boundaries of miniaturization, MPC’s micro-molded polyurethane components offer unmatched precision, customization, and performance. Using proprietary thermoset formulations, we produce parts as small as a dime, tailored for demanding applications in medical devices, defense systems, packaging, and semiconductor equipment. Unlike traditional thermoplastics, our advanced materials can be engineered for specific hardness, abrasion resistance, and coefficient of friction, giving designers the flexibility to meet exact functional and environmental requirements. Whether you’re prototyping or scaling to high-volume production, MPC’s micro molding capabilities deliver consistent quality and design freedom at every stage.

Solutions:

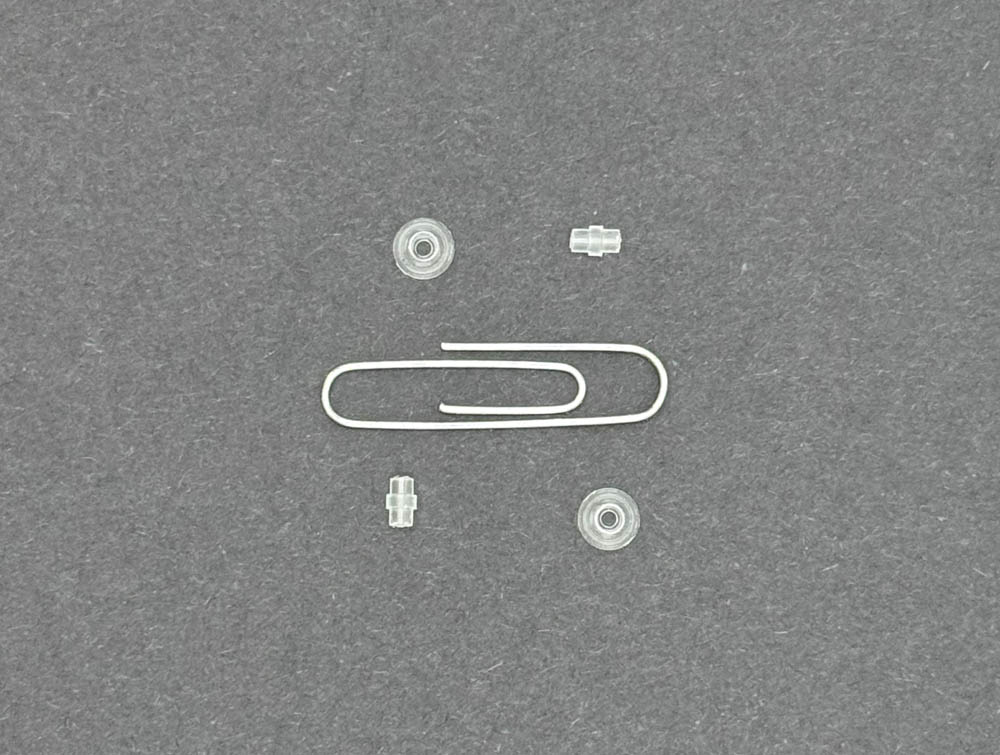

- Miniature Couplers or Dampeners

- Micro Drive Components

- Media Handling Grommets or Pads

- Custom Micro-Molded Products

Complete this form to access & download our technical documentation.

Product Spotlight – Micro-Molded Products

Mearthane’s micro-molded polyurethane products deliver exceptional precision, durability, and customization for industries where component size and performance are critical. Leveraging proprietary formulations and advanced molding techniques, these parts are ideal for medical devices, robotics, semiconductor, and other high-tech applications requiring tight tolerances and consistent quality at micro scale.

Key Advantages of MPC’s Micro-Molded Products:

- Micro-Scale Precision: Engineered for tight tolerances and intricate geometries at a micro scale

- Custom Material Formulations: Tailored materials to meet the most demanding performance specifications

- Agile Product Development: Rapid development cycles and scalable manufacturing for fast market entry

- Tooling Expertise: In-house mold design ensures repeatability and cost efficiency for difficult micro-molded products

- ISO 9001:2015 Certified: Trusted by OEMs in regulated and mission-critical applications

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

Micro-Molded Polyurethane Components for Complex Systems

MPC’s micro-molded products are designed to meet the evolving demands of compact, high-precision systems across industries like medical diagnostics, defense, automation, and consumer electronics. Our thermoset polyurethane formulations allow for tight tolerances, tailored mechanical properties, and repeatable performance—even at micro scale. Whether you’re integrating components into high-speed media transport systems or developing next-gen wearable tech, MPC’s micro molding capabilities ensure that every part—no matter how small—delivers big results.

Advantages of MPC’s Custom Micro-Molded Products:

- Precision Engineering: Consistent geometry and finish for tight-tolerance assemblies

- Material Versatility: Wide range of durometers, conductive options, and FDA-compliant formulations

- Scalable Production: Seamlessly transition from rapid prototyping to high-volume manufacturing with consistent quality

- Design Freedom: Enables complex part geometries at the micro scale

Case Study

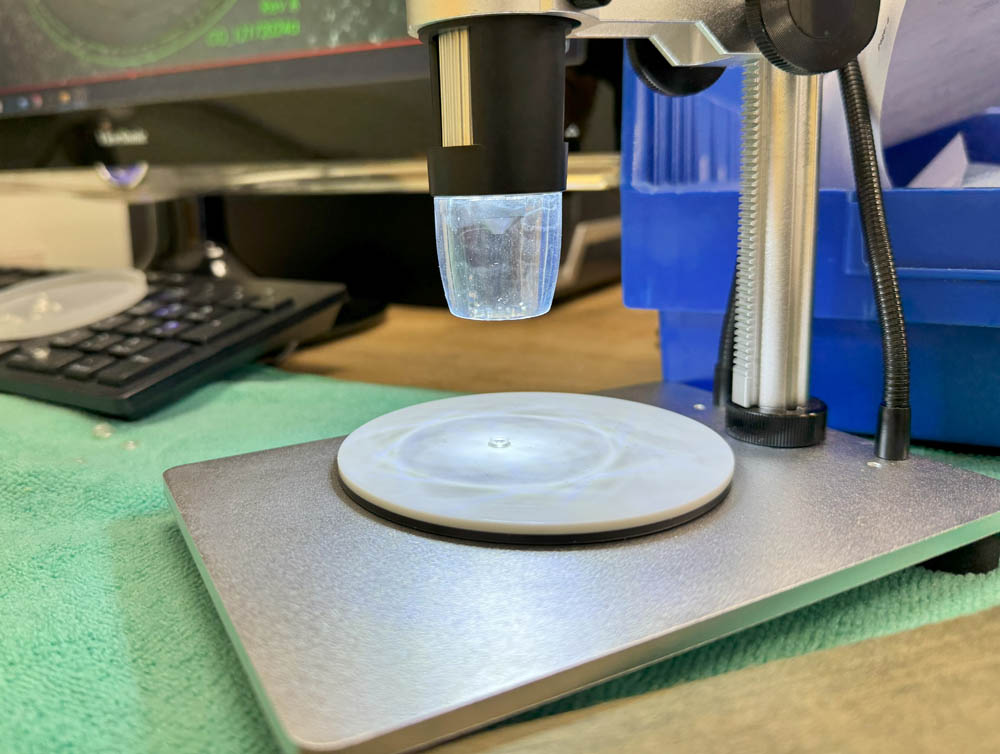

A leading OEM in semiconductor manufacturing equipment turned to MPC to help scale production of a critical wafer handling component amid rising global demand. The part, smaller than a dime, featured complex geometry, variable wall thicknesses, and ultra-tight dimensional tolerances, making traditional molding processes insufficient. MPC’s engineering team developed a specialized thermoset polyurethane molding process that delivered consistent, high-precision parts while enabling rapid production ramp-up. Following a rigorous engineering validation process, the customer successfully introduced the component into its systems, supporting a growbuming installed base and reinforcing its reputation for reliability in mission-critical semiconductor applications.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.