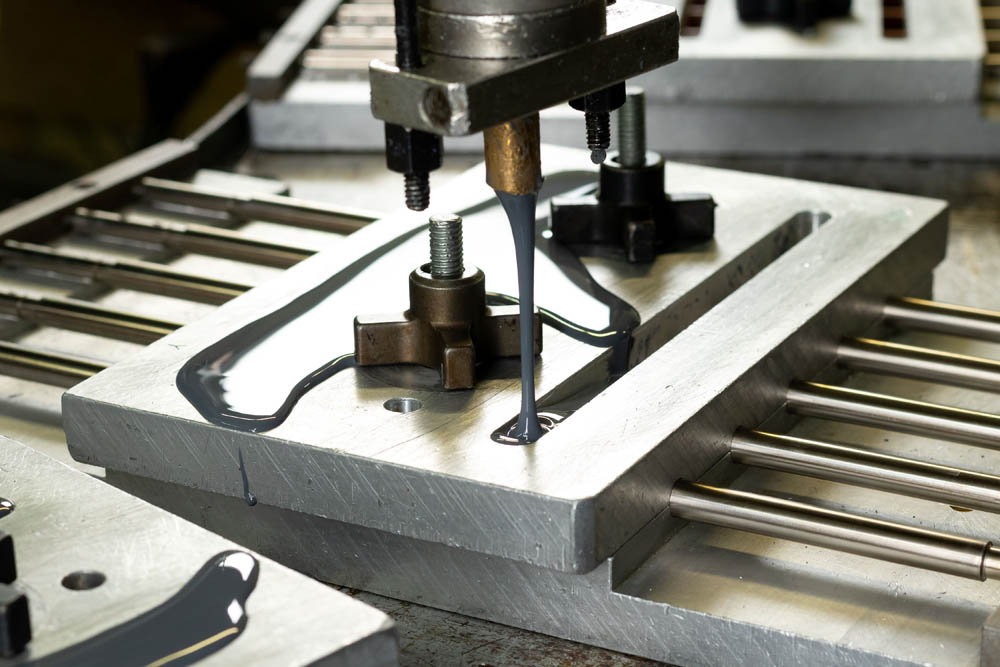

Cast Molding

Our flexible molding techniques deliver tight tolerances and handle complex geometries efficiently and consistently. Whether you need short runs, high-volume production, or micro molded parts, we mold to your specifications with precision and repeatability.

Capabilities

- Diverse cast molding techniques

- Innovative micro molding solutions

- Tight tolerance tooling design

Complete this form to access & download our technical documentation.

Adaptable Molding Capabilities for Every Application

Cast molding is at the heart of MPC’s manufacturing technology, enabling us to deliver custom polyurethane parts with precision, consistency, and scalability. Whether you’re developing a prototype or ramping up for high-volume production, our cast molding techniques are tailored to meet your unique design and performance requirements. From simple shapes to complex geometries, we match the right process to your application, ensuring repeatability, tight tolerances, and material optimization.

Some of MPC's Cast Molding Processes:

- Open & Closed Casting: Adaptable for both basic and intricate parts, based on geometry and production quantities

- Compression Molding: Ideal for uniform cross-sections and tight dimensional control

- Centrifugal Molding: Perfect for cylindrical components requiring concentricity and consistent wall thickness

- Hand-Poured & Automated Casting: Scalable from quick-turn prototyping to high-volume continuous production

Our engineering team is ready to review your requirements and recommend the best solutions. Contact us today to discuss your specific needs

Advantages of Cast Molding with Polyurethanes

Cast molding offers distinct advantages for product designers seeking flexibility, speed, and material performance. Unlike injection molding, which requires expensive hard tooling and thermoplastic materials, cast molding uses simpler, lower-cost molds and is optimized for thermoset polyurethanes-materials known for their superior abrasion resistance, chemical durability, and broad durometer range. This process enables rapid prototyping with soft molds, allowing for faster iteration and validation before scaling to production. Cast molding is ideal for low to high volumes, complex geometries, and applications where precision and adaptability are critical to success.

Key Advantages of Cast Molding:

- Material Versatility: Supports a wide range of thermoset polyurethane formulations for tailored performance

- Lower Tooling Costs: Multiple mold options allow for lower upfront tooling investment

- Rapid Prototyping: Enables fast iteration and design validation without long lead times or big tooling expenses

- Flexible Volumes: Ideal for low to high production runs, from small quantities to hundreds of thousands

Case Study

An offshore energy customer approached MPC to replace a machined metal enclosure used in a sensitive electronic assembly exposed to harsh marine conditions. Their existing solution was costly, prone to corrosion, and difficult to scale. Leveraging our cast polyurethane process, we engineered a custom enclosure that met stringent dimensional and performance specifications while offering superior resistance to saltwater, humidity, and temperature extremes. The result was a durable, lightweight alternative that not only outperformed marine-grade metals in corrosive environments but also delivered substantial cost savings and streamlined production, helping the customer scale efficiently without compromising reliability.

If you’re designing a new product and need a manufacturing partner who brings value from day one, contact us today to get started!

MPC Knowledge Center

Learn all about product design using polyurethanes. Use the tabs to view some of our top articles, or browse the full Knowledge Center to explore more.