When it comes to selecting the right material for your custom belts, two common options are polyurethane and PVC. Each has distinct advantages depending on the specific demands of your application. Polyurethane belts, particularly thermoset polyurethanes, are renowned for their superior durability, flexibility, and load-bearing capabilities. But how do they stack up against PVC belts?

Contact us today to discuss your specific requirements and find out which material is best suited for your application.

What is Polyurethane?

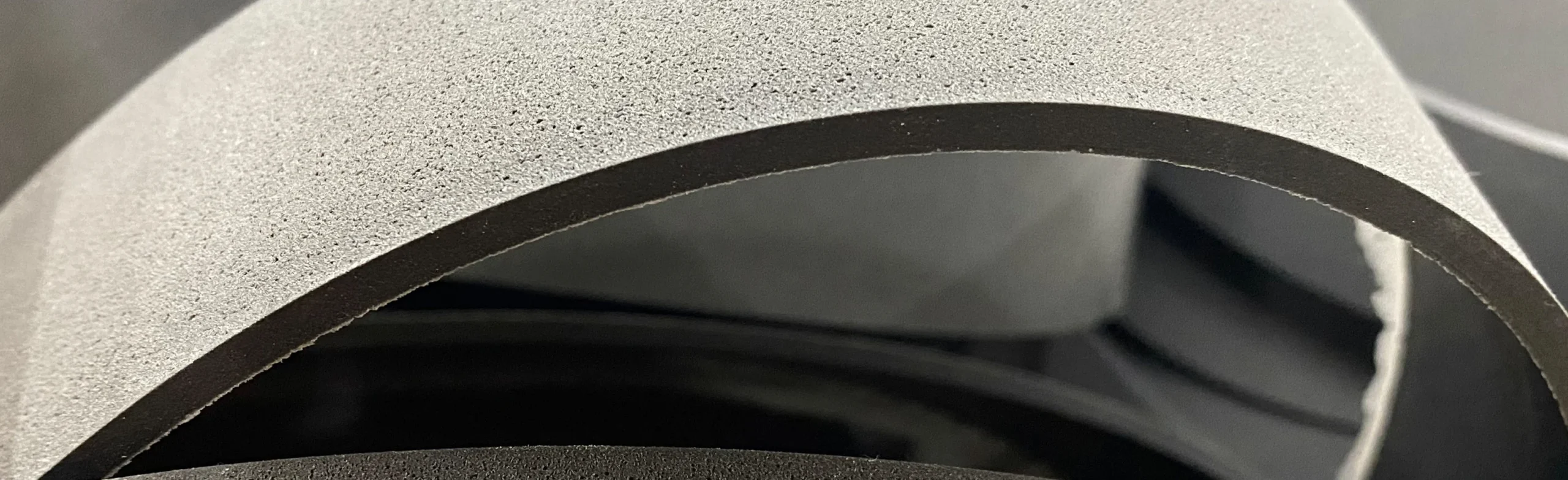

Polyurethane, especially thermoset polyurethane, is a versatile material known for its durability and resilience in demanding environments. Unlike its thermoplastic counterpart (TPU), thermoset polyurethane undergoes a chemical curing process, which means it becomes permanently set and is less likely to deform under high heat or stress. This makes it an excellent choice for belts that need to withstand heavy loads, abrasion, and extreme conditions.

Key benefits of thermoset polyurethane belts include:

What is PVC?

- Cost effective option

- Moderate durability

- Good flexibility in light applications

- Resistant to certain chemicals and moisture

Key Differences Between Polyurethane and PVC Belts

| Feature | Polyurethane Belts | PVC Belts |

| Durability & Strength | Superior resistance to wear, tear, & abrasion; does not deform under stress | Less durable; more prone to cracking under heavy loads |

| Flexibility & Performance | Customizable physical properties; can be engineered for various performance needs | Less flexible, especially under harsh conditions; may become brittle over time |

| Environmental Resistance | Excellent resistance to extreme temperatures, chemicals, oils, & UV rays | Less resistant to heat, cold, and chemical exposure; may degrade faster |

| Load Bearing Capacity | High load-bearing capacity without stretching or failure | Lower load-bearing capacity; may deform under stress |

| Cost vs. Performance | Higher upfront cost, but offers better long-term value in high-demand applications | More affordable, but may not meet high-performance needs |

Which is Right for Your Application?

The material you choose depends on the demands of your specific application:

- For heavy-duty, high-performance applications that require resistance to abrasion, extreme temperatures, and chemical exposure, thermoset polyurethane is the superior choice

- For lighter-duty applications where cost-efficiency is the priority and extreme resistance to wear is not necessary, PVC belts may be a sufficient option

Both polyurethane and PVC belts have their place in various industries, but when it comes to demanding, high-performance applications, thermoset polyurethane stands out as the material of choice. Its durability, flexibility, and environmental resistance make it ideal for a wide range of industrial uses.

Contact us today to learn more about how our custom polyurethane solutions can enhance your operations, and let us help you select the appropriate material for your needs.